UV Nano Imprint Lithography through the Web

Modules standard with system include:

- Unwind

- Coating Station- Gravure

- UV NIL

- Rewind

Product Description and Features

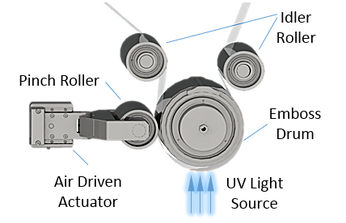

The basic process of nano imprint lithography requires a fluid to flow into the features of a roll stamper or roll master. This requires a fluid of sufficiently low viscosity, pressure to force the fluid to flow, and corresponding time for the fluid to fill the features. Any two of these parameters determine the third. In the UV systems, up to 50 pounds can be exerted on a pinch roller forcing the coated web into the stamper. The viscosity is determined by the UV curable fluid selection along with the fluid temperature. The speed and roller compliance set the time for the filling of the features and the resulting residual layer thickness or RLT.

Once the stamper features are filled, the material is cured. The cure is initiated with a prescribed dose of UV light. This UV light can be administered through the web, assuming an external UV source and a UV transparent web. In this case, the stamper may be made of electroformed nickel sleeve or shim(s) or perhaps on a laser or diamond machined sleeve.

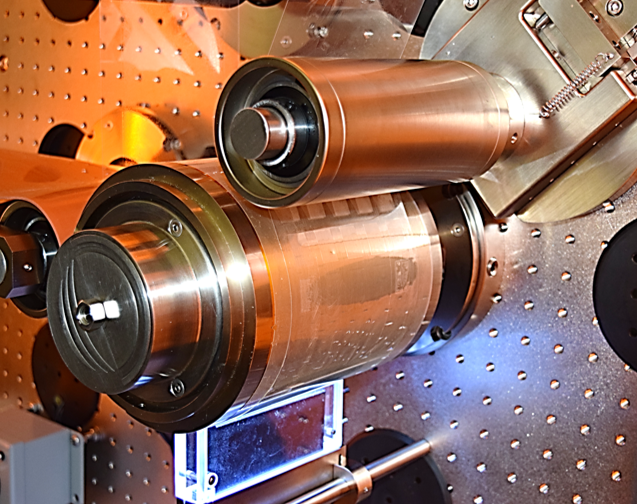

Each of the possible NIL modules provide a set of common process infrastructure. The module is mounted on granite which floats on active air isolation. The web tension entering and exiting can be adjusted from low to no tension to minimize disturbance from sound waves traveling through the material. The vacuum rollers are made to be low vibration, again communicating very little vibration to the web, thus insuring integrity of the printed pattern

TECHNICAL SPECIFICATIONS

UV LED LIGHT DATA

| Exposure Uniformity | <5% |

| Wavelength | 365nm |

| Light Source Size | 150mm |

| Cooling Method | Water Cooled |

| Brightness Control | 0-10V |

| Input Power | 48V |

COATING-GRAVURE DATA

| Coating Thickness | .5-100um |

| Accuracy of Coating Thickness | 2-5% |

| Viscosity Range | 20-100000cP |

| Speed Range | 5-800in/min |

| Width | 6in |

| Roll Diameters | <1in |

| Wet Thickness | 2-100um |