Systems

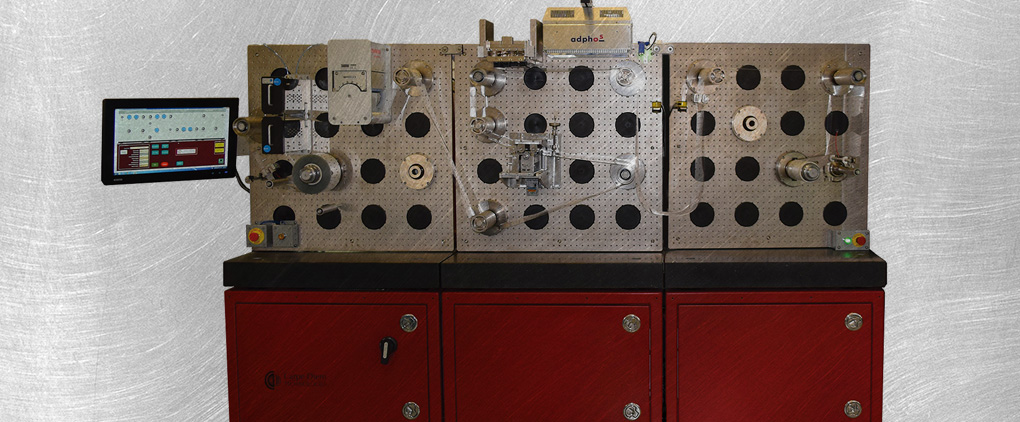

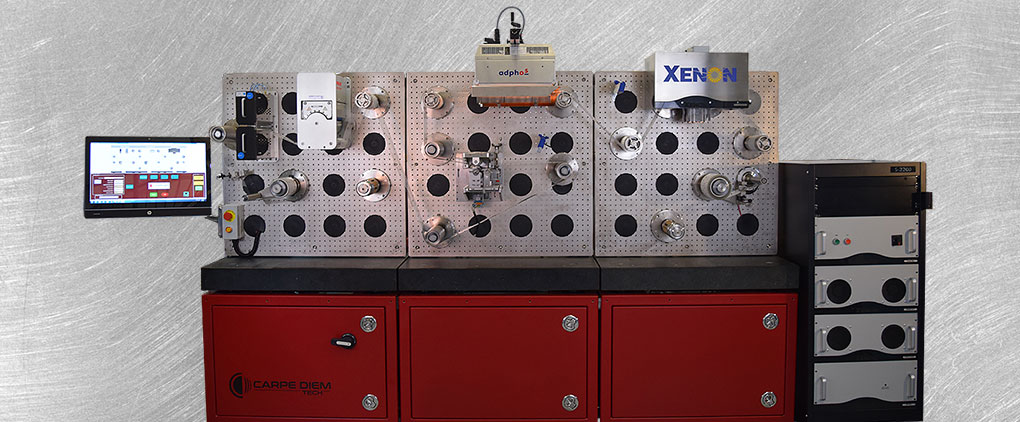

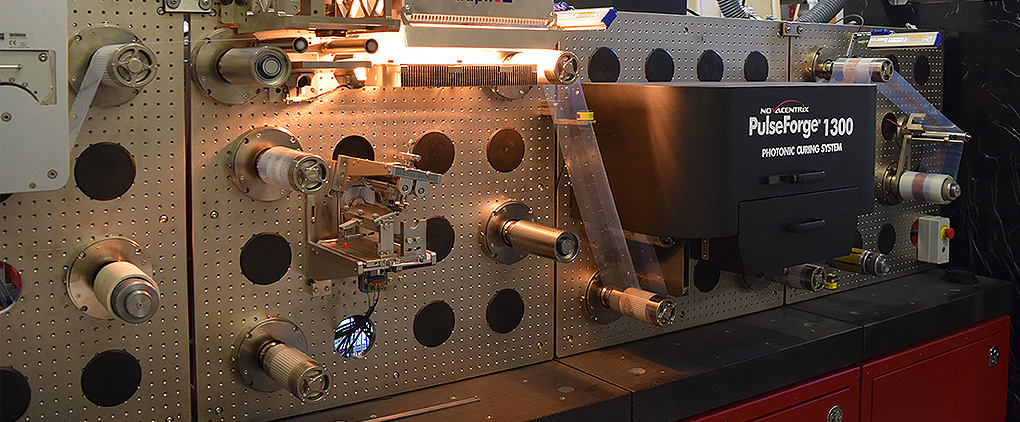

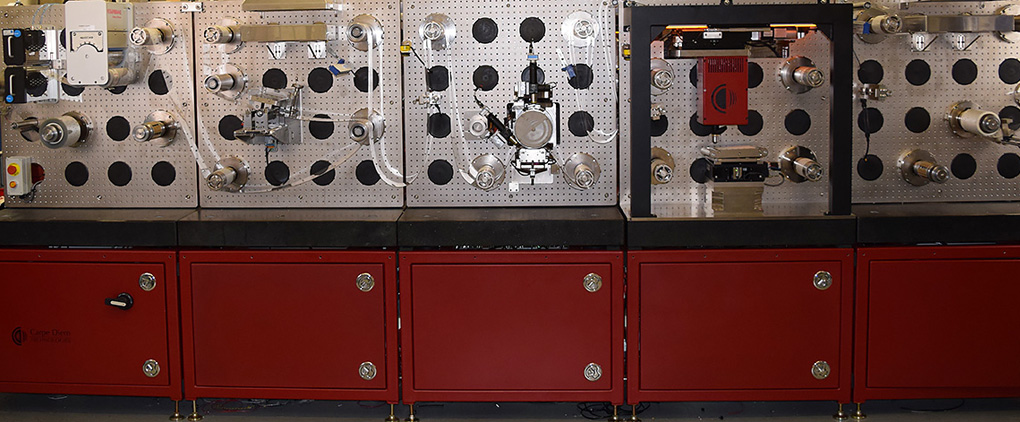

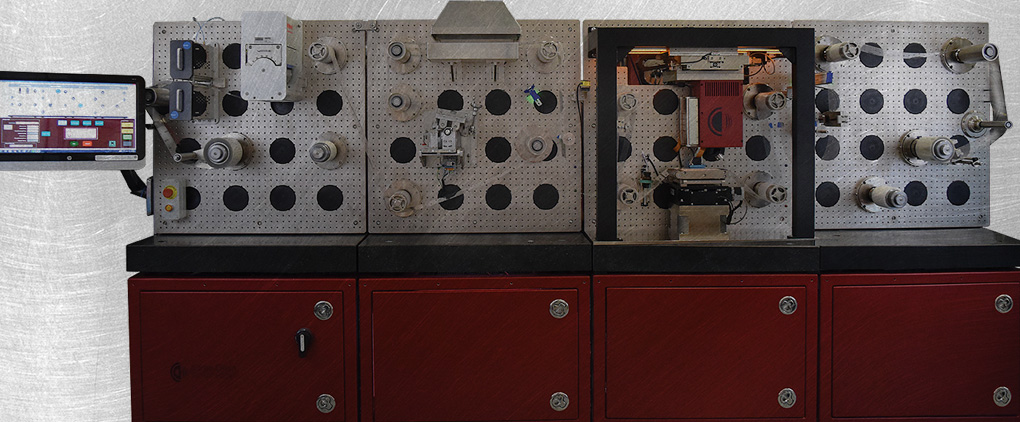

We provide unique advanced process capabilities in a modular web handling system with complete integrated control which allows a flexible substrate to be brought into the system, unwound, tracked and pretreated with cleaning, corona or plasma. The web is fed into the targeted process, then tracked and rewound.

All of our systems are integrated with an HMI interface with smart access to the critical control parameters governing a process. All systems consist of the required Unwind & Control Module and then up to 6 of an available 10 different modules daisy chained together to create a process line. Carpe Diem or 3rd party Components can be added conveniently by the user to the system.

Advanced processes and capabilities with Carpe Diem unique developments include:

- Nano Imprint Lithography

- Spatial Atomic Layer Deposition

- Direct Write (Maskless) Lithography with TI DLP9000

- Contact Lithography and Alignment

- Interferometric Alignment and Inspection

- Optical Alignment

- Inkjet

Each process step (unwind, targeted process, rewind) takes place on its own three-foot-wide modular frame, daisy chained electrically and physically. This allows easy transport, easy reconfiguration, and extendibility for future requirements. Up to 6 modules (of an available 10) can be chained together to build a greater than 18-foot-long web process line.

CENTAURI Coating and Printing System

Nano Imprint Lithography

Inkjet Coat & Anneal System

Contact/Proximity Lithography Aligner System

DW Lithography Stepper Aligner System

Coating System