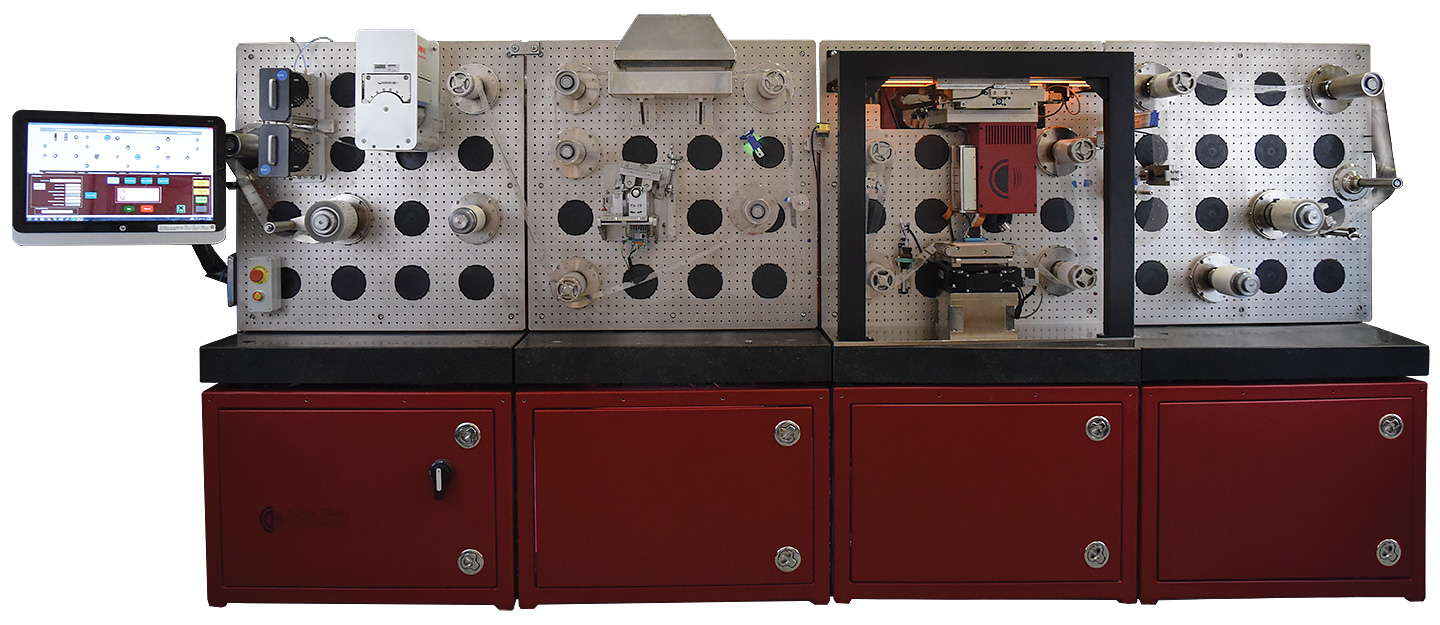

DW Lithography Stepper Aligner System

Includes 4 modules:

Unwind and Control + Coat w/Prebake + DW Stepper Module + Rewind

The Carpe Diem Stepper Aligner System provides the capability to unwind and pretreat a flexible substrate or web, coat with photoresist then prebake and perform aligned high resolution direct write from a digital file photolithography or inkjet on flexible and even distorted substrates.

The integrated Carpe Diem Direct Write Stepper Module provides the means for high resolution alignment of one digital pattern from a stored file to another existing pattern on the web, thus combining multiple printing and lithographic steps.

High speed direct write is made possible with Texas Instrument’s DLP9000™. The DLP9000 contains more than 4 million micromirror pixels at a pitch of 7.56 microns. These are projected through optics to provide up to a 10X reduction in size yielding a minimum lateral addressable feature resolution at .756 microns. LED UV light at 365 nm, 385 nm or 405 nm can be specified for exposure with up to 1 watt optical power available.

This high UV throughput light engine has been combined with a Carpe Diem interferometric and optical vision system. This unique combination provides the means to find high contrast relief patterns and precisely align with the DLP UV projected image or an optional integrated inkjet with a positioning error as low as .2 microns.

Applications

- Multilayer printed electronics

- Microfluidic devices

- 3D Printed structures aligned

Additive and subtractive technology integration

DW Lithography Module