Nano Imprint Lithography

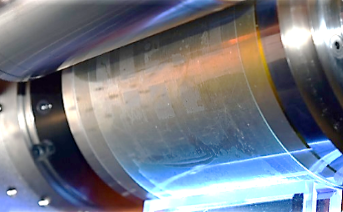

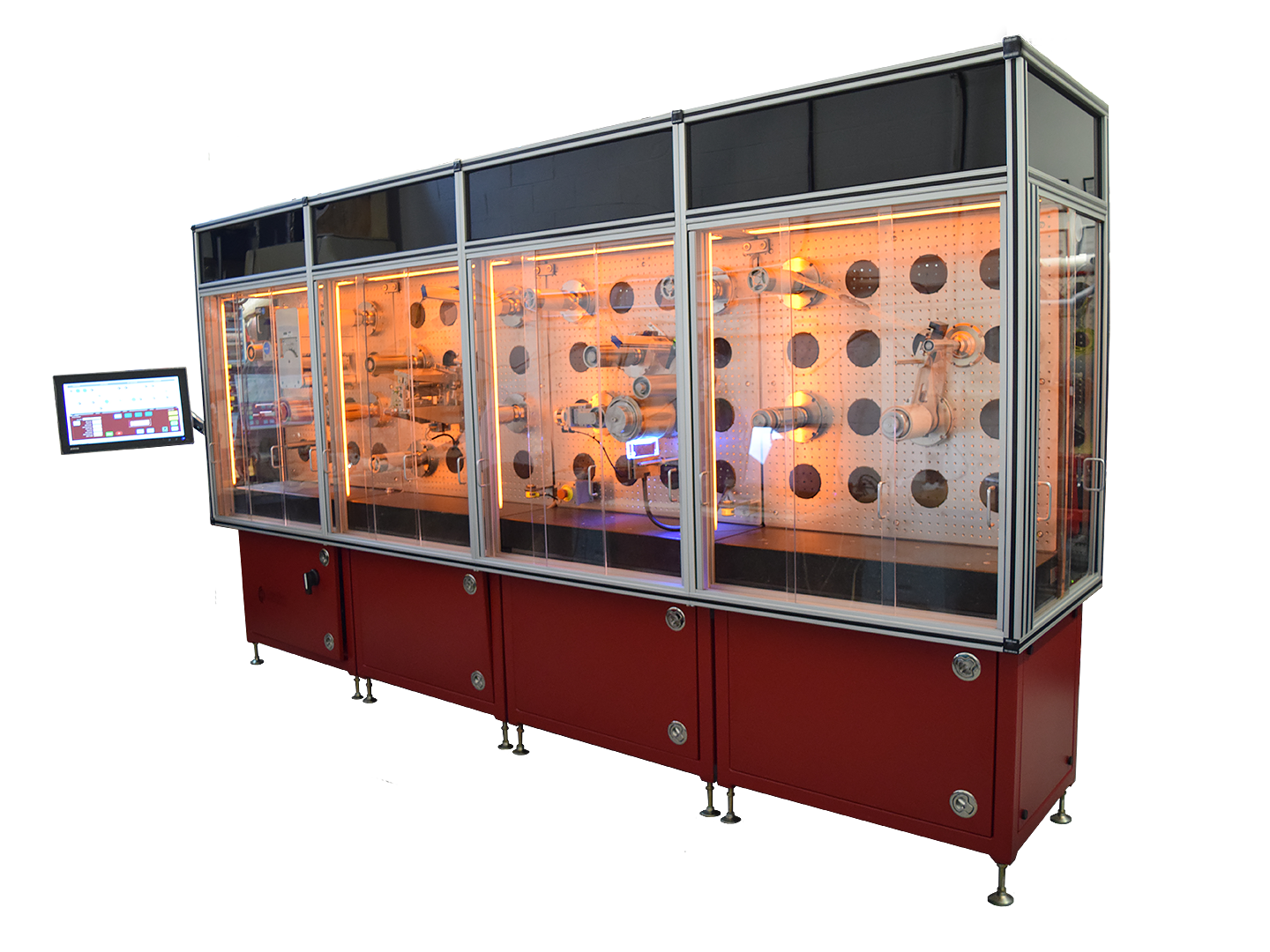

The Carpe Diem Nano Imprint Lithography system provides the capability to unwind and pretreat a flexible substrate or web, coat with photoresist, and then imprint nanometer or micron scale features from a PDMS, nickel or other master or stamper to a web and then rewind. This system can be provided with NIL modules for UV exposure through a transparent substrate, UV exposure through the mask for opaque substrates or for thermal emboss of thermoplastic substrates or coatings.

The Carpe Diem Nano Imprint Lithography system provides the capability to unwind and pretreat a flexible substrate or web, coat with photoresist, and then imprint nanometer or micron scale features from a PDMS, nickel or other master or stamper to a web and then rewind. This system can be provided with NIL modules for UV exposure through a transparent substrate, UV exposure through the mask for opaque substrates or for thermal emboss of thermoplastic substrates or coatings.

Meta materials – Hydrophobic, Super Hydrophobic, Antibacterial, Magnetic, Structural color…

- Waveguide, diffractive and micro refractive optics

- Hologram production

- Multilayer printed electronics

- Additive, no develop masking

- Microfluidic devices

- Pharmaceutical micro capsules

- Direct “single step” material patterning

- Water Purification

- Batteries

- Thin film organic electronic devices

Benefits of R2R NIL are:

- Cost Efficient

- High Resolution

- Flexible Inexpensive Substrates

- High Throughput

- Fast and Accurate method for Structure transfer

- UV or Thermal curing of resist

- Versatility (ability to change geometries, structure size, etc.)

The Nanoimprint Lithography systems created by Carpe Diem Technologies include:

Roll-to-Roll Nanoimprint Lithography enables development and production of low cost, large-area nano-materials and devices.

TECHNICAL SPECIFICATIONS OF SYSTEMS

| Speed | 3in/min up to 800in/min (100mm/min up tp 20000mm/min) |

| Web Width | 6 in to 12 in (150mm to 300mm) |

| Web Thickness | 10μm up to 250μm |

| External Roll Diameter | Maximum 6in @ 6 in Web Width |

| Web Tensile Stress | Typical 0-5lbs nominal tension |

| Materials | PC,PMMA,PET,PS |

Other sizes and options available upon request

Request More Information About Nanoimprint Lithography