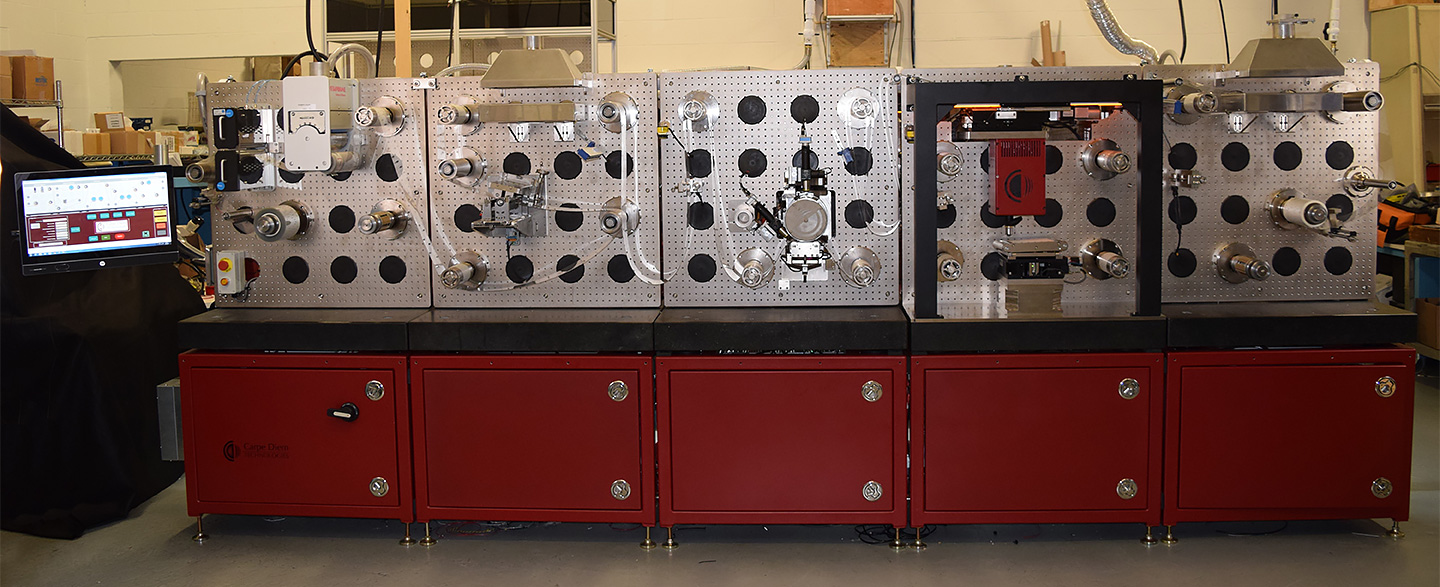

Contact/Proximity Lithography Aligner System

Includes 4 modules:

Unwind and Control + Coat w/Prebake + Contact Align + Rewind w/Postbake

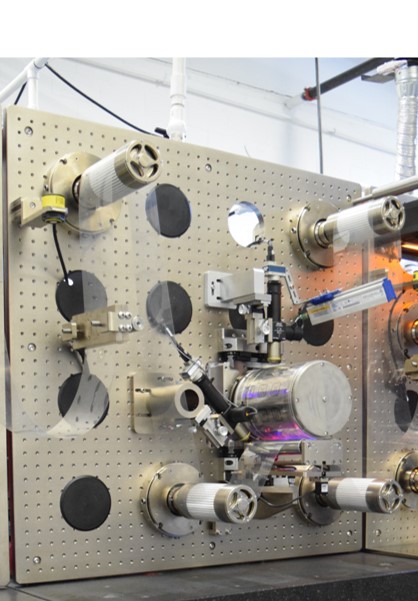

The contact or proximity optical lithography system provides the means for alignment and exposure through a 6” x 18” mylar or flexible glass mask that has been affixed to a rotating, nominally 6 inch diameter, UV transparent drum. Exposure occurs through the mask as the web passes by the synchronized rotating drum. Proximity is monitored by two epsilon triangulation sensors. Within the drum, a collimated UV laser is scanned orthogonal to the surface of the drum by a rotating polygon with appropriate optics. Also contained within the drum is a vision system monitoring overlay error between web and masks.

The system has two other cameras for alignment feedback and calibration. One on the drum monitoring the mask and drum and one monitoring web position and timing. There are five axes of alignment control. The system has the capability to monitor and correct to micron level or better depending on microscope objective and encoder selection, alignment is limited by web distortion, web handling and speed. Mylar masks and collimation provide a limit to best resolution attainable. Locally, resolution of 2-5 micron is attainable.

Contact Proximity Lithography Aligner Module