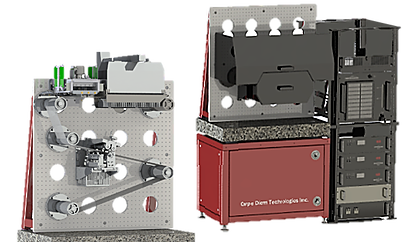

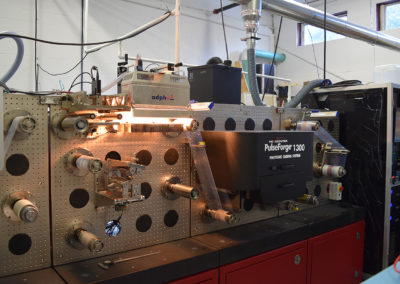

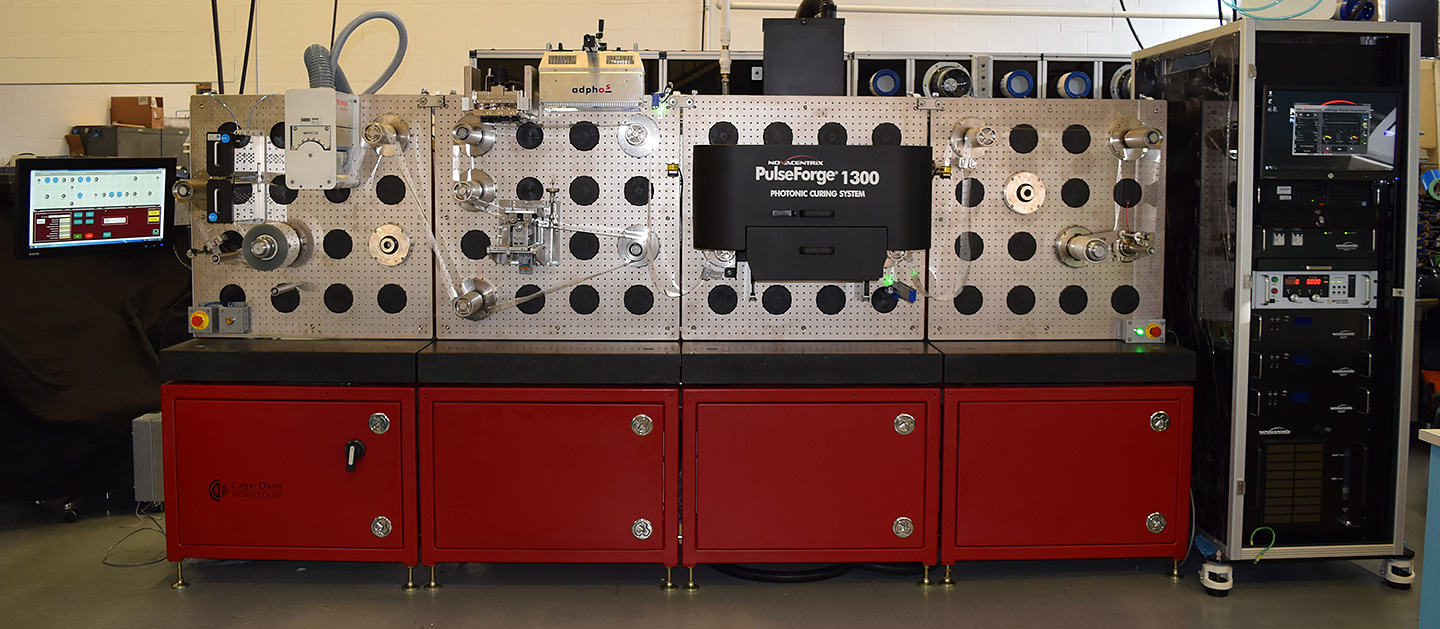

Inkjet Coat and Anneal System

Modules standard with system include:

- Unwind

- Coating- Inkjet with optional Gravure

- Pulse Forge 1300

- Rewind

- PF Power Supply

This Photonic Curing system expands the possibilities of curing not attainable with a conventional oven process. Photonic curing has the ability to anneal or sinter nano particle inks and thin films on low temperature inexpensive substrates, such as paper or plastic. This is enabled by the high-intensity flash lamp which heats the spectrum absorbing ink to its melting point or sintering temperature without correspondingly heating the transparent or reflective substrate.

The high intensity fast duration pulse results in heating the absorbing material faster than the heat can diffuse into the surrounding substrate. Copper nano-ink, for example, can be melted on the surface of plastic or paper. This results in a sharp reduction in the electrical resistance as the nanoparticles which touch only tangentially now are fused into a continuous surface.

Photonic curing has the ability to create new materials that were previously unattainable with an oven. The limitations of equilibrium in thermal processes restricted the use of certain materials, with the pulse systems these materials can now be utilized. Materials of interest include the manufacture of graphene, sintering of high temperature ceramics, and many conductors.

Inkjet Features

- Leading method of creating flexible electronics.

- Adjustable digital pattern

- Does not require masks or templates to print

- Prompt error correction

- Fast turnaround, ability to upload information to interface and print on web instantly

- Uses low viscosity and low concentration ink formulations

- Non-contact printing

- Low operation cost

- Low ink consumption with inexpensive substrate

- Wide range of inks

- Suitable for electronics on flexible substrate

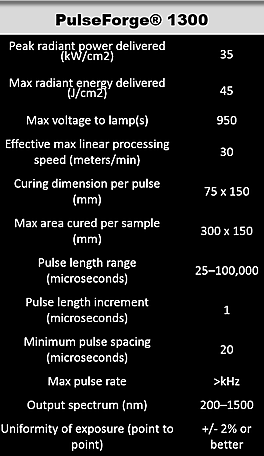

TECHNICAL SPECIFICATIONS

| Speed | 4 in/min up to 80in/min (100mm/min up to 20000mm/min) |

| Web Width | 6 in |

| Web Thickness | 10um up to 250um |

Phonic Curing Processes:

- Annealing

- Sintering of metals and ceramics

- Instant drying of thin films

- Modulating and initiating of chemical reactions

Example Uses:

- Processing of novel photovoltaic materials

- Batteries

- Displays

- Sensors

- Logic and Memory

- Capacitive touch and Medical sensors

- Medical Field

- Disposable printed biosensors

- Energy harvesting devices

- Wearable flexible electronics

- NFC antennas for smart packaging